In mold structure machining, tool interference is a phenomenon which results from a collision between a blade of tool and a workpiece. Also tool collision is a phenomenon which results from a collision of holder with the object to be machined. These p...

http://chineseinput.net/에서 pinyin(병음)방식으로 중국어를 변환할 수 있습니다.

변환된 중국어를 복사하여 사용하시면 됩니다.

- 中文 을 입력하시려면 zhongwen을 입력하시고 space를누르시면됩니다.

- 北京 을 입력하시려면 beijing을 입력하시고 space를 누르시면 됩니다.

금형 구조부 가공을 위한 효율적 공구 충돌 알고리즘 조사 = Review of Effective Algorithms for Tool Collision in Mold Structure Machining

한글로보기https://www.riss.kr/link?id=T10232405

- 저자

-

발행사항

서울 : 성균관대학교 대학원, 2005

-

학위논문사항

학위논문(석사) -- 성균관대학교 대학원 , 산업공학과 , 2005. 8

-

발행연도

2005

-

작성언어

한국어

-

주제어

collision ; algorithms ; mold

-

발행국(도시)

서울

-

형태사항

66p ; 26cm

- DOI식별코드

- 소장기관

-

0

상세조회 -

0

다운로드

부가정보

다국어 초록 (Multilingual Abstract)

To detect a collision of a tool to mold structure, first of all, the mold structure and a tool must be defined with famous geometric models such CSG, B-rep, and Voxel. A tool is defined as a combination of the blade, the shank, and the holder.

This thesis reviews various collision detection algorithms using z-map and computer 3D graphic collision detection algorithms for the tool in machining a mold structure. Especially, those algorithms have been reviewed based on their effectiveness. The effectiveness of an algorithm can be defined as its accuracy, less memory size, and fast computational speed. Based on this research, both the characteristics of the collision detection algorithm have been summarized, and more effective method`s for detecting collisions have been proposed.

In mold structure machining, tool interference is a phenomenon which results from a collision between a blade of tool and a workpiece. Also tool collision is a phenomenon which results from a collision of holder with the object to be machined. These phenomena not only cause damages to mold and tool but also increase machining time and cost.

To detect a collision of a tool to mold structure, first of all, the mold structure and a tool must be defined with famous geometric models such CSG, B-rep, and Voxel. A tool is defined as a combination of the blade, the shank, and the holder.

This thesis reviews various collision detection algorithms using z-map and computer 3D graphic collision detection algorithms for the tool in machining a mold structure. Especially, those algorithms have been reviewed based on their effectiveness. The effectiveness of an algorithm can be defined as its accuracy, less memory size, and fast computational speed. Based on this research, both the characteristics of the collision detection algorithm have been summarized, and more effective method`s for detecting collisions have been proposed.

목차 (Table of Contents)

- 목차

- 제 1 장 서론 = 1

- 1.1 연구배경 = 1

- 1.2 연구목적 및 범위 = 6

- 제 2 장 공구형상과 공구간섭 = 8

- 목차

- 제 1 장 서론 = 1

- 1.1 연구배경 = 1

- 1.2 연구목적 및 범위 = 6

- 제 2 장 공구형상과 공구간섭 = 8

- 2.1 공구형상 구조 = 8

- 2.2 가공물과 공구의 형상 모델링 = 11

- 2.3 공구 간섭과 충돌 = 17

- 2.3.1 공구간섭 = 17

- 2.3.2 모의 가공을 이용한 공구 충돌 검출 개념 = 19

- 2.3.3 가상공간에서 충돌 검출의 개념 = 20

- 2.3.4 효율적 알고리즘 정의 = 21

- 제 3 장 Z-map에 관한 연구 = 23

- 3.1 Z-map을 이용한 연구 = 23

- 3.2 피삭재 형상을 Z-map 데이터구조로 표현한 연구 = 27

- 3.3 복합 곡면 가공에 있어서의 공구 간섭 방지에 관한 연구 = 30

- 3.4 다양한 공구 형상의 이동 궤적체를 이용한 연구 = 31

- 제 4 장 3D 충돌 검출 알고리즘에 관한 연구 = 35

- 4.1 다면체와 8분할(Octree) 형상 표현 방법 = 35

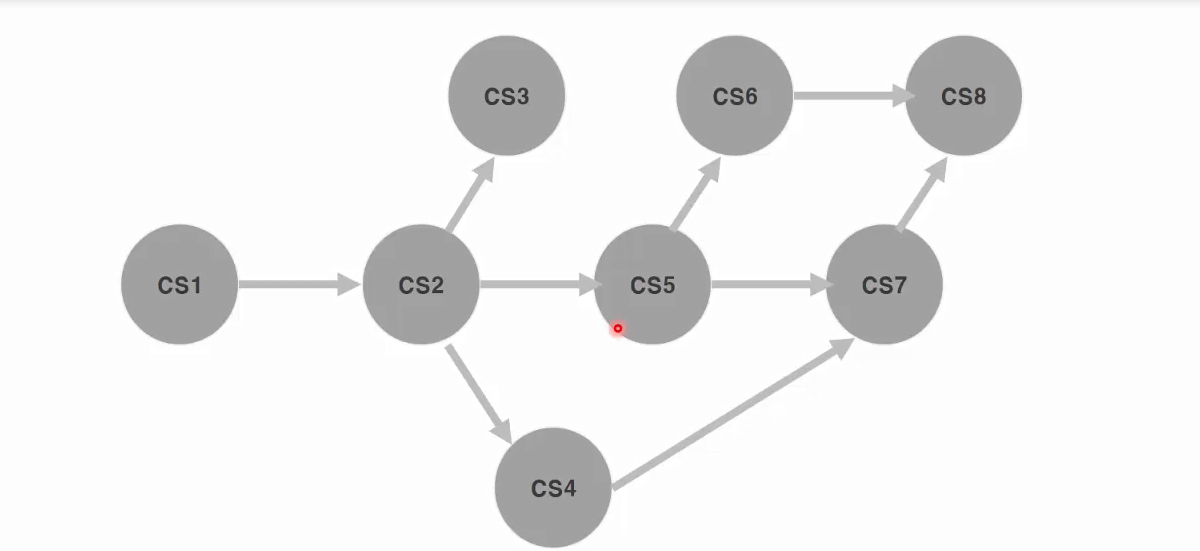

- 4.2 BVH(Bounding Volume Hierarchies)의 충돌 검출법 = 38

- 4.3 PQP(Proximity Query Package) 충돌 검출법 = 42

- 제 5 장 금형 구조부 가공을 위한 충돌검출 방법 요약 = 44

- 5.1 금형 구조부 가공 = 44

- 5.2 충돌 검출에 적합한 공구형상의 모델링 방법 = 47

- 5.3 금형 구조부에서 충돌 검출을 위한 방법 제안 = 50

- 제 6 장 결과 및 추후 과제 = 54

- 참고 문헌 = 57

- ABSTRACT = 65